- Ceiling: Diamond silver painted steel with acrylic photic board (HD-DTA01)

- Operating panel: Integrated operating panel

- Car wall: Hairline stainless steel

- Flooring: Standard PVC (FJ-B01) (optional marble)

- Car door: Hairline stainless steel

Scroll Down

Please take a moment to fill out the form. we will get back to you ASAP.

With the strong capabilities in designing, developing and manufacturing, FUJl aims at the diversified needs of clients and the various regional lift markets to develop the products in accordance with the diverse criterions. such as Asia Series, Europe Series, and North America Series, etc. Combining target market’s feature, FUJI continuously introduces, develops and investigates, to ensure industry-leading technologies and products all the time.

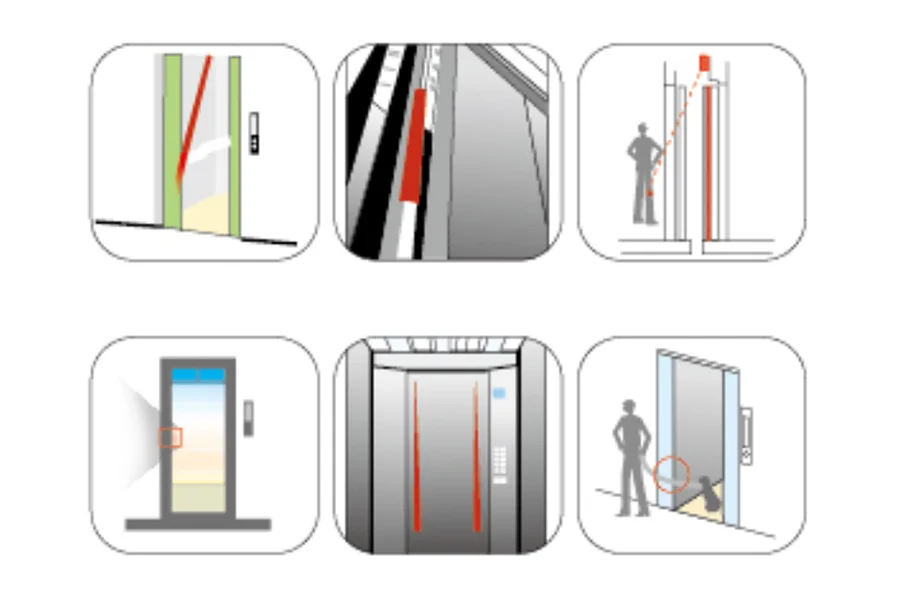

Integral control system represents the developing orientation of the elevator control system. It is new generation intellectual vector type integral control system. It covers distance control, direct parking, closed-loop vector control technology, CANBUS communication technology, multi-CPU running technology and applies C and assembly language programming. It perfectly combines the contemporary industrial control technology, communication technology and traditional elevator. Compared with the traditional elevator control, it brings about the higher cost performance and the more convenient maintenance.

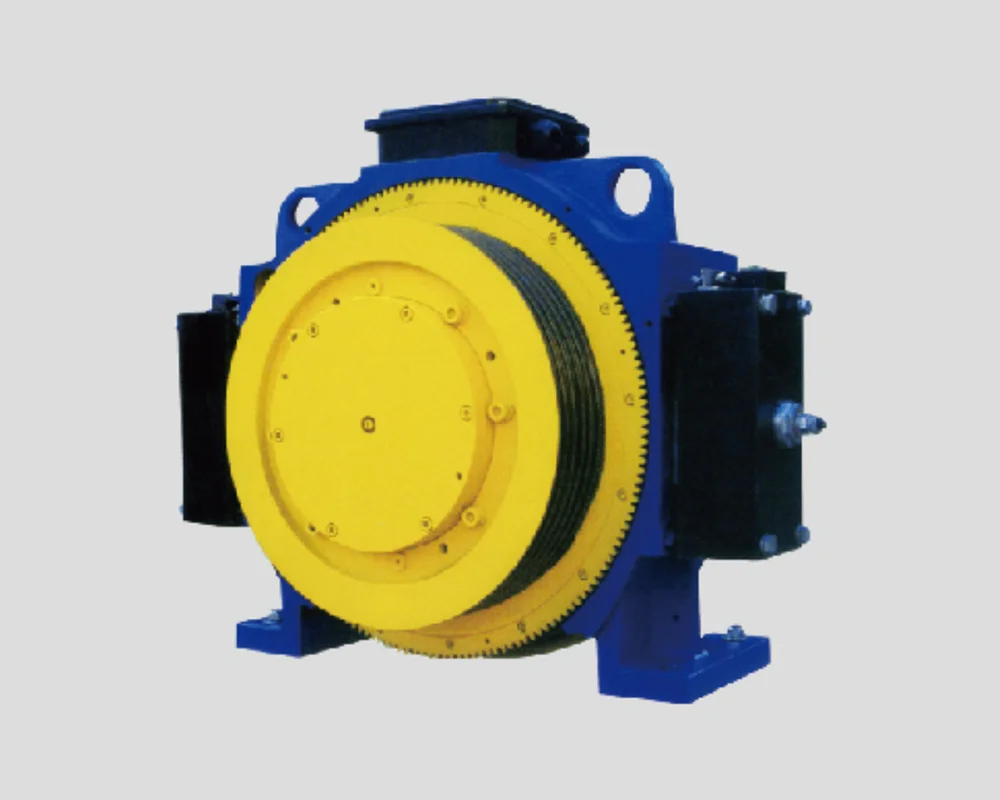

We choose rare earth material and fully combine coaxial transmission technology and digital variable frequency technology with group computer combined control technology. With less running cost & less energy dissipated. Compared with the ordinary and traditional technology, gearless traction machine can save more than 33% of the energy. Gearless traction machine needs no renewal of lubricant. Without grease pollution, low noise, quiet & natural.

Stay far away from city noise, enjoy a green space(Optional)

The peaceful running is below 50DB. It is obviously lower than the standard in the same industry. It greatly enhances the mute performance. It adopts no-vibration humane design, inner-rotor horizontal structure, high length-diameter ratio, the more reasonable structure, the more smooth operation, low braking noise, regulation-free clearance, low running temperature-rise, the longer service life, small bulk, light weight, space-saving, the more convenient installation.

FUJI small machine room passenger elevator only has about 65%~70% of the traditional machine room. It greatly saves the building space and material. Control cabinet in machine room is designed into single-face inspection layout. The host bearing beam can also be used as hitch plate. It largely saves the machine room space. Compared with the traditional elevators, under the premise of ensuring the repairers’ operation space which is stipulated by the national standard, it effectively controls the machine room height. The intensive space effect grants more freedom for the architects. It expands the larger space utilization to the construction, perfectly merges the well space with the architectural style.

Compared with FUJl small machine room elevator, machine room is only an extension of the elevator well. It brings about the more convenient installation, the lower cost as well.

Compared with the traditional traction machine, FUJI small machine room elevator consumed less energy and brings about low loss in heat energy as well.

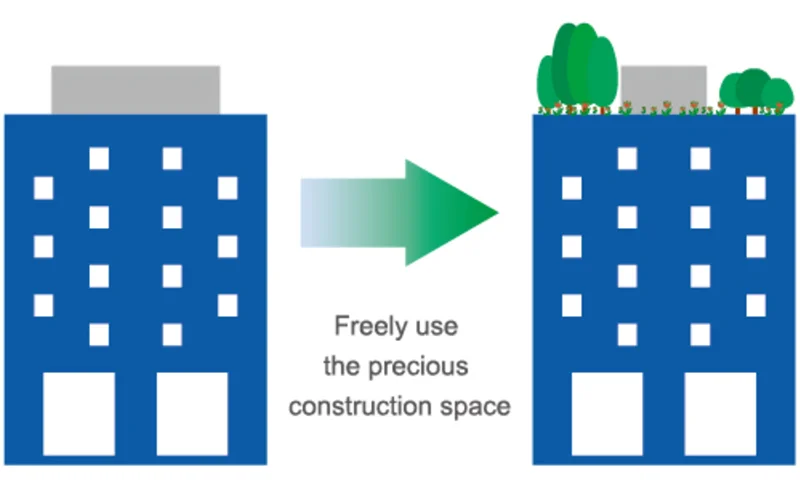

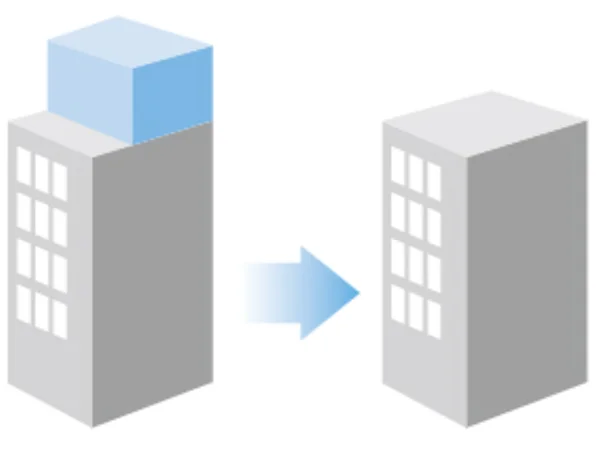

FUJI machine roomless passenger elevator cancels the machine room, reduces total area of the elevator equipment and flexibly utilizes the effective space. It has the stronger contemporary sense and the more beautiful construction outine.

The host and control device are designed at the shaft top to prevent from occasional water-inlet in the shaft which damages the drive device. In this way, it guarantees a highly reliable system.

FUJI machine roomless passenger elevator need only one independent hoist-way and do not need the presence of machine rooms. The architects and developers are allowed to conduct designing in a freer way.

We cancel the machine room to freely design the shaft position. We can flexibly and effectively apply the top space that is preset for machine room.